In their world, nothing stirs a watch enthusiast’s heart like spotting an exquisite dial on a luxury watch. Superb craftsmanship is synonymous with Grand Seiko; and that is why it is the unrivaled leader in dial artistry. Grand Seiko dials possess intricate textures and motifs deriving from nature’s beauty and crafted elegance—and they do not simply serve as a surface, rather, they tell a narrative.

At Evolution Watches, we have always admired the level of precision that goes into making the dials of watches. Let’s examine in greater detail how Grand Seiko fashions some of the most effortlessly beautiful and intricately detailed dials in the world from raw materials.

Design & Inspiration: Where Art Meets Nature

The Grand Seiko was inspired by stunning nature— and everything starts with inspiration. The brand’s design team analyzes surfaces and components like patterns and hues present in Japan’s scenery. Their striking dials are underpinned by natural phenomena, including snowcapped zeniths, birch woodlands, and glistening beautiful lakes.

In particular, stunning examples are:

- Snowflake Dial – Mimics the delicate snow of Shinshu.

- Birch Dial – Reflecting roughness of white birch trees.

- Mt. Iwate Dial – It captures the essence of Mount Iwate’s rippling ridges.

For the Iwate Dial, the design team considers how light, texture, and color interplay of the piece to ensure the final dial is dynamic as possible from every angle.

Base Dial Preparation: Selecting and Shaping the Base Material

The process starts by selecting the material which must be of utmost quality. For the dials of Grand Seiko, they predominantly make use of sturdier brass or silver-plated brass. Some special editions even go a step further and use more exotic materials such as:

- Aventurine glass for an effect evocative of a starry sky

- Urushi lacquer for deep and glossy finish

- Mother of Pearl for a soft, iridescent glow.

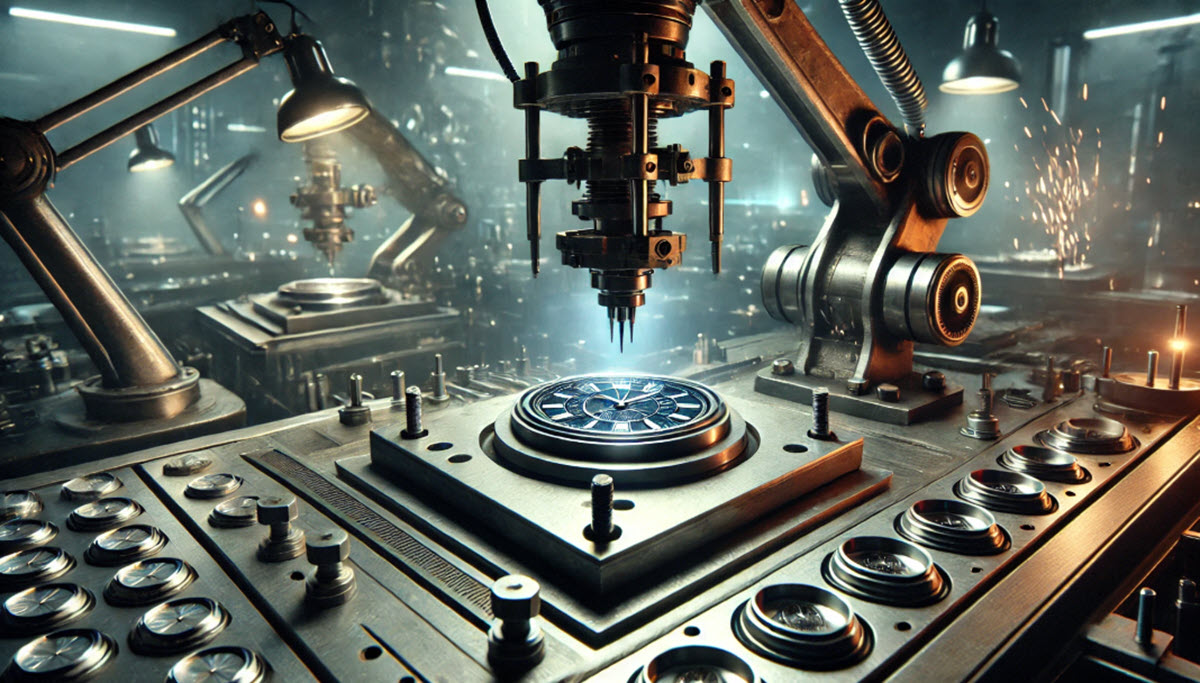

After these materials have been selected, the next step involves precision cutting the shape of the dial in the CNC computer-controlled machines. This stage also entails the cutting of windows for dates as well as other complications.

The next step entails polishing the dial in a bid to bring out all imperfections, and in this case, final polishing, preparing the piece for its most distinctive step — texturing.

Creating the Texture: Where Grand Seiko Stands Apart

This is when the magic happens, the moment most watch enthusiasts distinguish Grand Seiko from the rest of the luxury watch brands.

Press Stamping for Precision Patterns

The Grand Seiko dials such as the renowned Snowflake or Birch are made using a press stamping method. In this case, a die (which is a mold with the dial texture) is pressed into the metal with extreme force, sometimes surpassing 1,000 tons.

Such stamping of the dial causes extreme pressure to be applied giving the dial texture stirring tw o-and-a-half dimensional patterns that reflect light in a lovely manner.

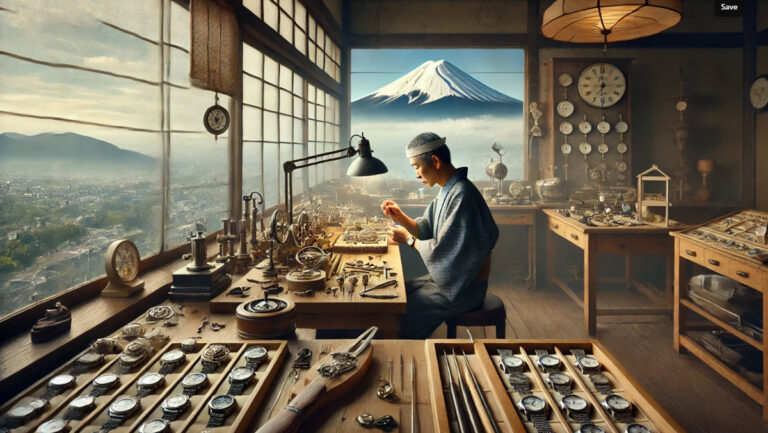

Hand-Engraving for Limited Editions

For certain special or limited edition models, Grand Seiko may choose to go for hand engraving. Expert craftsmen meticulously gouge the patterns onto the dials so that no two pieces are the same for a particular dial.

Embracing a conventional technique like this requires immense skill that is cultivated over a long period of time, which in turn makes the dials highly valuable.

Urushi Lacquer & Maki-e Techniques

In some cases, Grand Seiko incorporates their distinctly Urushi lacquered dials. This type of lacquer is known for its richness and depth as it is applied in thin layers one after the other. Fine gold powder may be added for delicate Maki-e embellishments too.

Such methods give life to the dial as the piece gains Masterpieces of Japanese art etched on its surface.

Coloring & Finishing: Bringing the Dial to Life

Once the texture of the dial is finished, the next step involves adding color and finishing touches.

Electroplating for Rich Colors

Electroplating or galvanization, which is more familiar to many, is an industry-standard process for achieving bright blue, gold, silver and even champagne shades. Color molecules are bonded onto the dial’s surface.

Lacquer & Enamel Coatings

Some Grand Seiko dials consist of hand-applied lacquer or enamel to achieve high gloss effect, especially with black, red or deep blue dials.

Sunburst & Gradient Effects

Numerous models have sunburst effects where the dial has been brushed radially before coloring to showcase light. Others employ fumé techniques which is a darker-to-lighter gradient.

Aventurine Glass for Starry Skies

Some models are made from aventurine glass which contains small reflective particles. These small particles give it a shimmering, night sky effect when set against light.

Adding Details: Printing & Indices

Markers, logos and other details can only be added after the dial’s surface has received finishing touches.

Text and minute tracks are printed at the correct angles with a specialized printer. For higher-end models, the Grand Seiko logo and the hour markers are applied by hand in polished steel or even gold.

Placing each detail, they are checked through a magnifying lens to ensure there is no mistake.

Zaratsu-Polished Hands & Indices: Grand Seiko’s Defining Characteristics

Grand Seiko employs the masterful Zaratsu technique to polish the brand’s signature hands and indices. This polishing method produces distortion-free and mirror-like surfaces with sharp vortices.

As with all visual components of a timepiece, this polishing also improves its legibility, making it easier to read without compromising artistry.

Final Assembly & Quality Control

Each Grand Seiko watch face undergoes multiple quality steps before it ever enters the case.

The brand pays extra attention to each dial for:

- Dust and other imperfections

- Color and texture uniformity

- Reflection and movement of light

- Placement of hands, markers, and text with relative spacing, all markers zero

Only after these thorough inspections is the dial mounted to its case and mated to a Grand Seiko movement ready for sale.

Closing Remarks: What Makes Grand Seiko Dials Special

Every Grand Seiko watch face is not only beautiful, but embodies a combination of modern technology and centuries-old Japanese craftsmanship with the artistry underneath.

Each piece of beauty is a masterpiece of:

- Texture: Any blends of surfaces patterned within a surface.

- Craftsmanship: Acceptable levels of skillful mechanical work blended with handwork.

- Inspiration: Bottling nature in the form of miniatures.

The craftsmanship and detail that goes into Grand Seiko dials puts them among the most sought after in the horology world.

Evolution Watches shares the vision that Grand Seiko has reimagined a new standard for luxury dials. With Grand Seiko, every dial is a narrative waiting to be told — one that speaks not only of time but also of the culture, the meticulous artistry, and the relentless strive towards excellence that it embodies.